Drilling and tapping heatsinks

Drilling and tapping of heatsinks is precision work. We can drill 0.1 mm holes in 1 mm stainless steel!

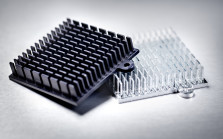

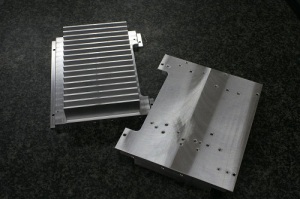

Processes that are applied on a large scale are the flattening of the bottom to which the components will be attached and making tap holes.

Heatsinks often require special hole patterns. We customize them completely to your preferences. Blind holes too, by which we remove a part of the fins, in order to allow bolts with bolt heads to fit well.

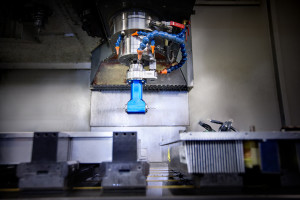

Tap holes at face side

We can make (tap) holes in different sides of a heatsink by using a 4th axis or an angular head. This way, we can provide lengths up to 1.5 m with holes at face side.

Options drilling and tapping heatsinks

- Hole patterns

- Blind holes

- Tap holes at face side (with lengths up to 1.5 m)

- Apply fixing holes for attaching components

- Apply fixing holes for attaching the heatsink to its position in the machine

- Fixing holes with or without screw thread

- All types and sizes, both cut and form tapped

- Press stainless steel or steel inserts into aluminium to strengthen the screw thread